Hi, I am Yafang Wu.

Pronounced /yʌfɑŋ/, or "Yah-fun."

Electrical Engineer

Since the age of 15, engineering has held a profound fascination for me. I love engaging with challenging ideas, exploring innovative problem-solving approaches, and creating unconventional yet exceptional solutions.

Contact MeAbout Me

Introduction

I graduated from Rensselaer Polytechnic Institute in 2023 with a deep

passion for a multitude of engineering disciplines, and my diverse background provides me with

unique insights, allowing me to come up with unexpected yet awesome solutions to problems.

As I seek out opportunities in the field, I am continuously expanding my knowledge and skills in different engineering disciplines, I am currently working toward my E.I.T. Certification in Electrical and Computer Engineering. After all, there is always something new out there!

Experience

Completed

Skills

Technical CompetenceC++

IntermediateMATLAB

BeginnerPython

AdvancedAutodesk Fusion 360

ProficientCadence Virtuoso

IntermediateLogicWorks

BeginnerSiemens NX

ProficientSOLIDWORKS

ProficientSkills

3D Printing

ProficientCAD

ProficientEmbedded Controls

IntermediateEngineering Design Process

AdvancedIntegrated Circuit Design

BeginnerMicrocontrollers

IntermediateLaser Cutter

ProficientMachine Shop Tools

AdvancedMicrocontrollers

IntermediateRenewable Power Generation

IntermediateSensors

AdvancedSimulink

BeginnerVLSI Design

BeginnerProjects

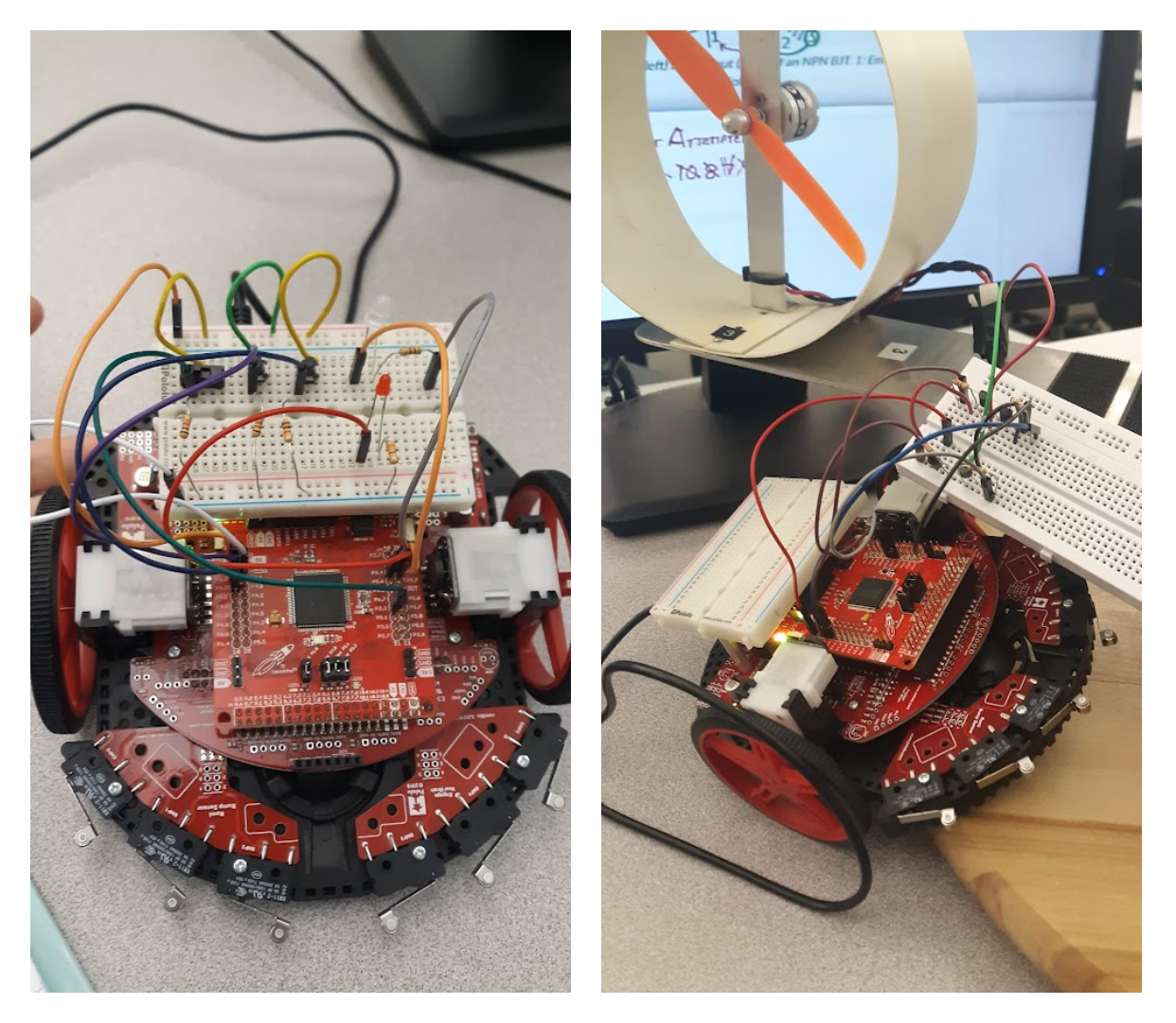

Skills applied: 3D

printing, Bluetooth Beacon, CAD, Design Analysis, Design Report, Project

Development, Prototyping, Schematics, Sensors(LiDAR, IMU), Wiring.

In collaboration with Boeing professionals, the

team at RPI aimed to revolutionize aircraft exterior scanning, creating a precise

digital twin for failure inspection with 0.5in precision, documenting failure point

imagery, and coordinates.

Responsibilities encompassed project development, CAD design, 3D printing, Bluetooth

beacon creation, prototype testing, and integrating LiDAR and IMU sensors.

Skills applied: 3D

printing, Bluetooth Beacon, CAD, Design Analysis, Design Report, Project

Development, Prototyping, Schematics, Sensors(LiDAR, IMU), Wiring.

In collaboration with Boeing professionals, the

team at RPI aimed to revolutionize aircraft exterior scanning, creating a precise

digital twin for failure inspection with 0.5in precision, documenting failure point

imagery, and coordinates.

Responsibilities encompassed project development, CAD design, 3D printing, Bluetooth

beacon creation, prototype testing, and integrating LiDAR and IMU sensors.

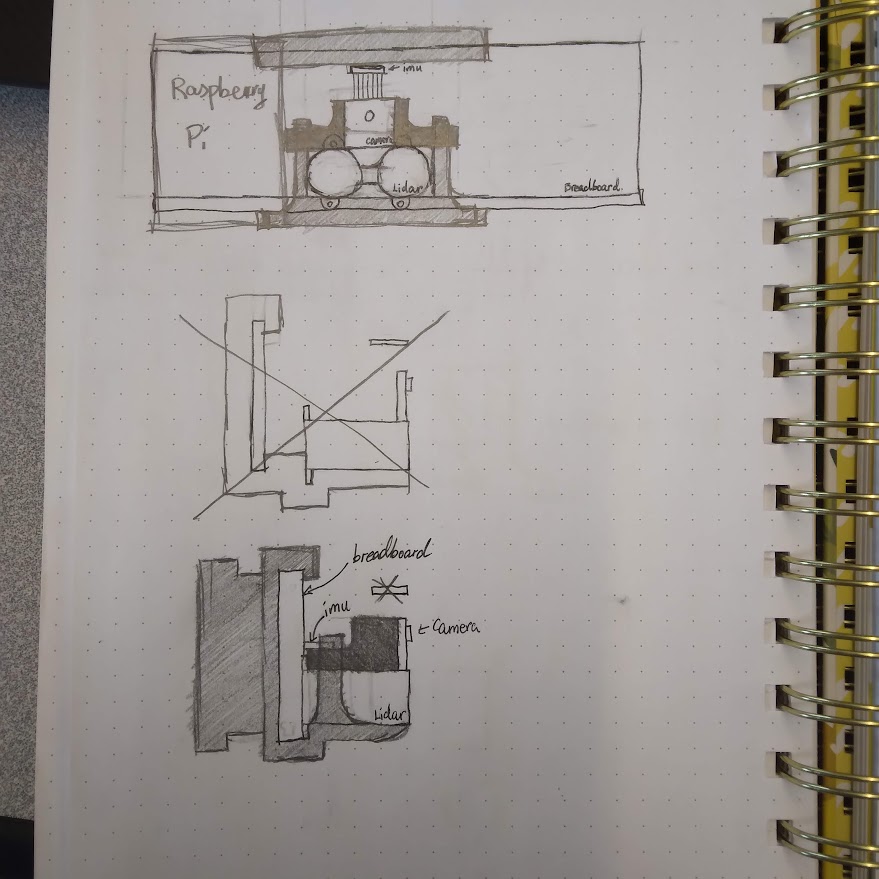

The image depicts the initial mount design for the

electronic components, employing interlocking mechanism for effortless disassembly

during inspections, eliminating the need for screws or glue.

The image depicts the initial mount design for the

electronic components, employing interlocking mechanism for effortless disassembly

during inspections, eliminating the need for screws or glue.

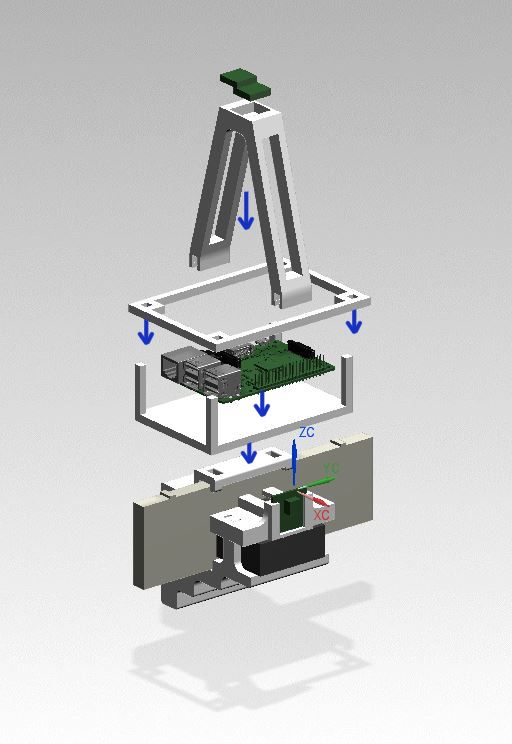

The CAD rendering displays the electronic mounts

designed for easy disassembly and quick access to its components. Calculations

factored in 3D printing material expansion and tolerances to ensure optimal

functionality

The CAD rendering displays the electronic mounts

designed for easy disassembly and quick access to its components. Calculations

factored in 3D printing material expansion and tolerances to ensure optimal

functionality

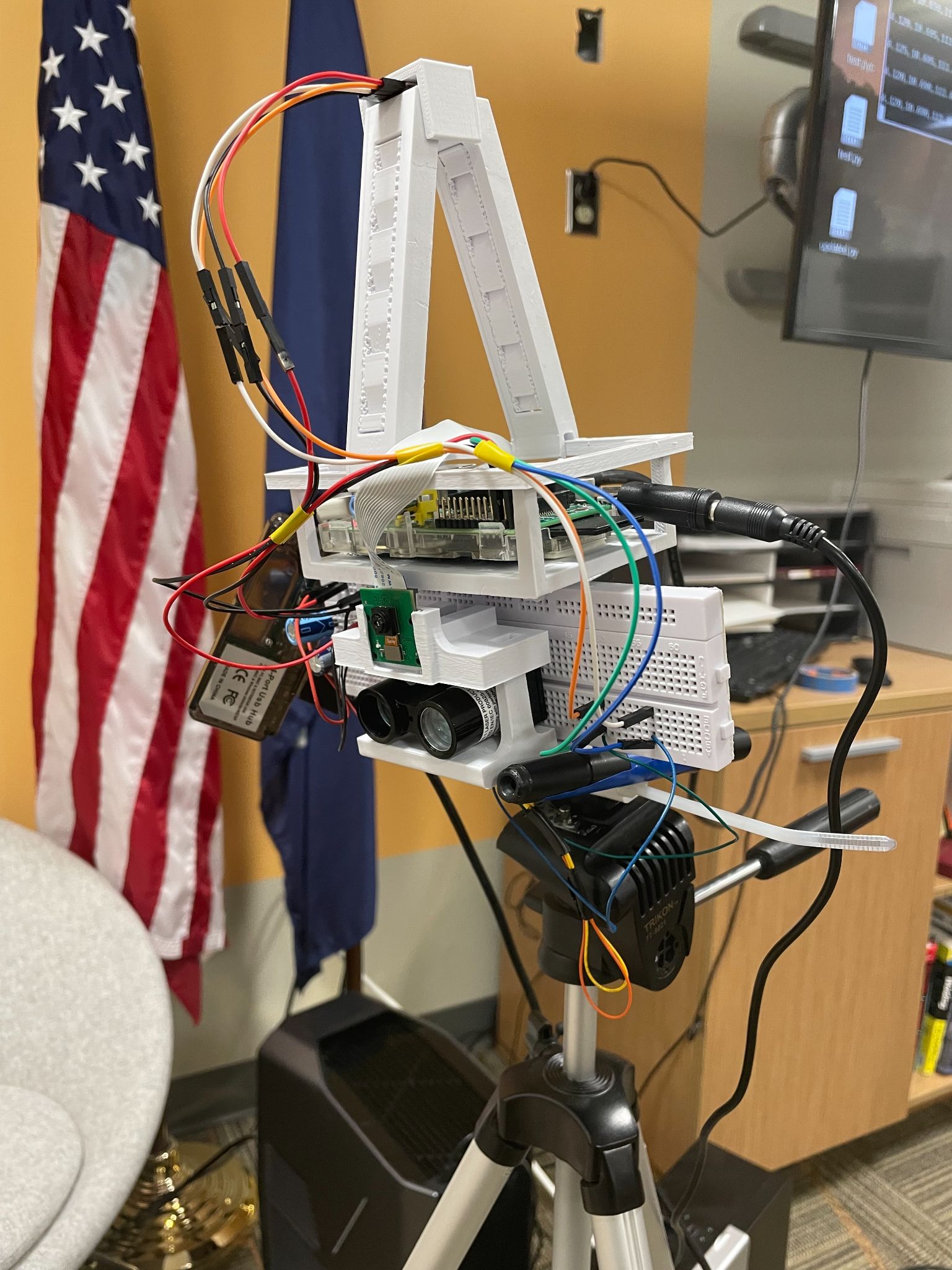

The image captures the testing phase of the

assembly, accessing both output precision and electronic noise interference.

The image captures the testing phase of the

assembly, accessing both output precision and electronic noise interference.

Skills applied:

Arduino, Bluetooth,

Laser Beam, Laser Cutter, Living Hinge, Motors, Power System, Project Development,

Resistors(Photoresistor, Potentiometer), Schematics, Soldering, Wiring.

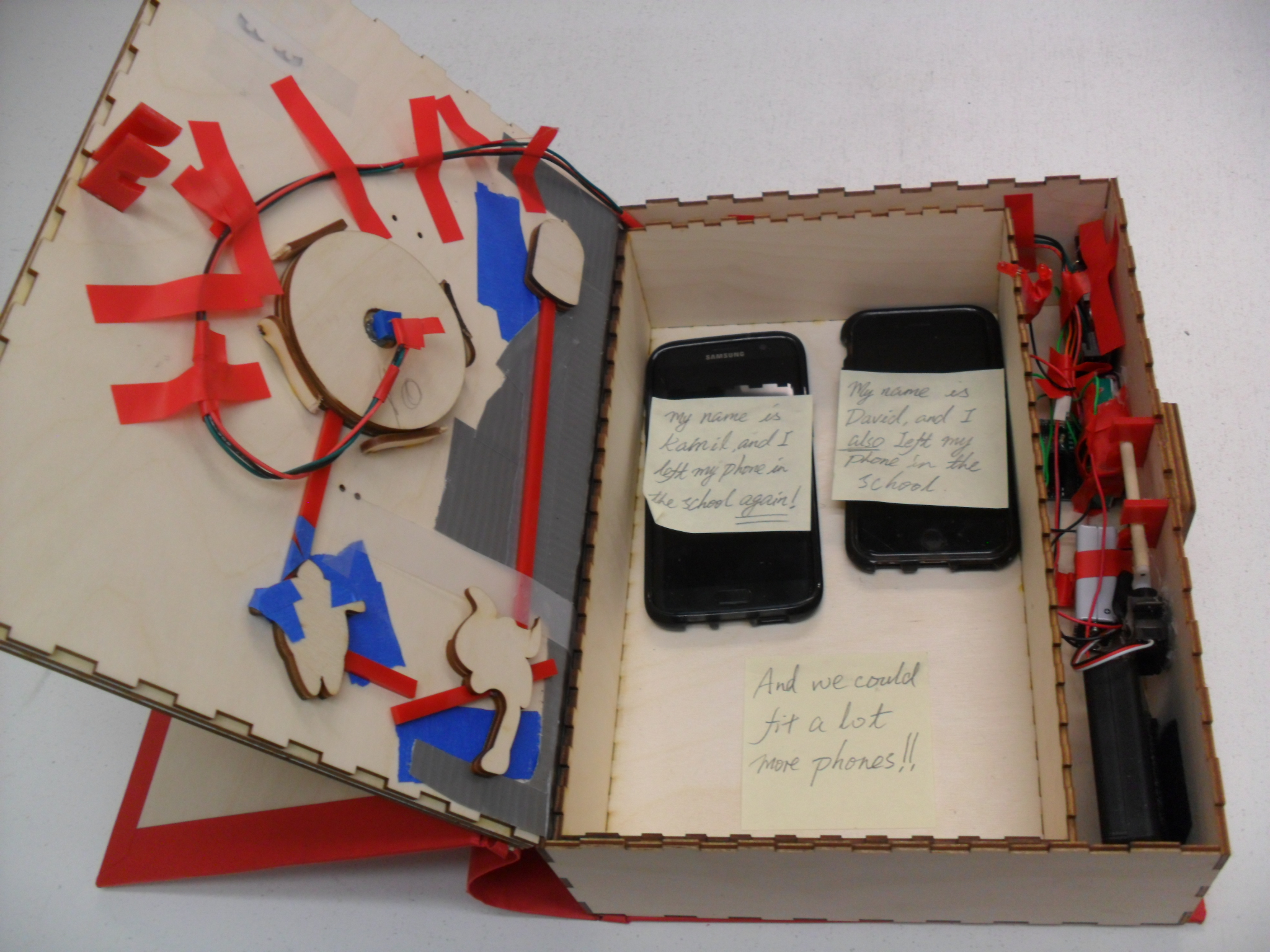

The puzzle box features intricate locking

mechanisms requiring precise adjustments, including decorative elements, remote

keys, and a yin-yang symbol. Crafted without 3D CAD, it showcases advanced spatial

visualization and laser cutting skills. Illuminated dragon eyes indicate progress,

and its dictionary-like design blends seamlessly with other books, offering both

practicality and novelty.

Skills applied:

Arduino, Bluetooth,

Laser Beam, Laser Cutter, Living Hinge, Motors, Power System, Project Development,

Resistors(Photoresistor, Potentiometer), Schematics, Soldering, Wiring.

The puzzle box features intricate locking

mechanisms requiring precise adjustments, including decorative elements, remote

keys, and a yin-yang symbol. Crafted without 3D CAD, it showcases advanced spatial

visualization and laser cutting skills. Illuminated dragon eyes indicate progress,

and its dictionary-like design blends seamlessly with other books, offering both

practicality and novelty.

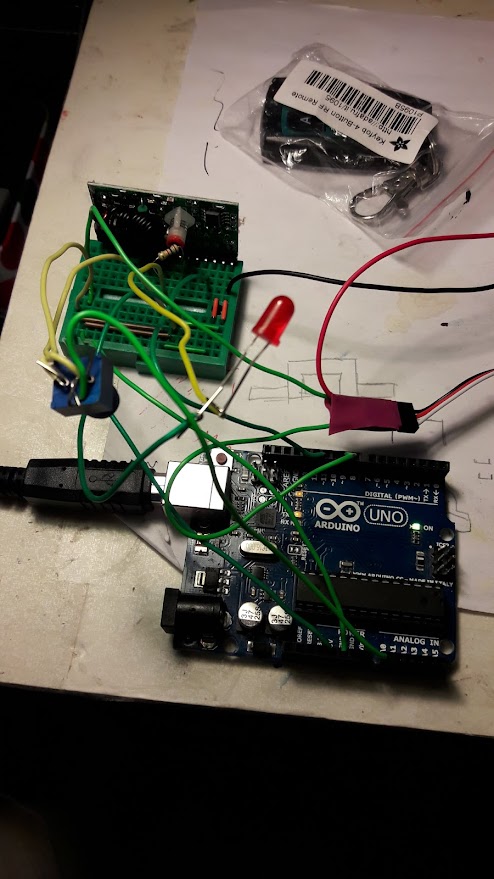

The image depicts a Bluetooth remote controlling

circuit, integrated with Arduino, undergoing testing alongside a potentiometer.

The image depicts a Bluetooth remote controlling

circuit, integrated with Arduino, undergoing testing alongside a potentiometer.

The image depicts the practical use of the puzzle

box, where two individuals who forgotten their phones overnight engaged in puzzle

solvings to retrieve their devices the following day. This not only offered a secure

place for lost and found, but also provided an enjoyable interactive activity that

many people participated in.

The image depicts the practical use of the puzzle

box, where two individuals who forgotten their phones overnight engaged in puzzle

solvings to retrieve their devices the following day. This not only offered a secure

place for lost and found, but also provided an enjoyable interactive activity that

many people participated in.

The image depicts the second iteration of the

puzzle box, integrating new design features like light reflection, laser beams,

photoresistors, and living hinges.

The image depicts the second iteration of the

puzzle box, integrating new design features like light reflection, laser beams,

photoresistors, and living hinges.

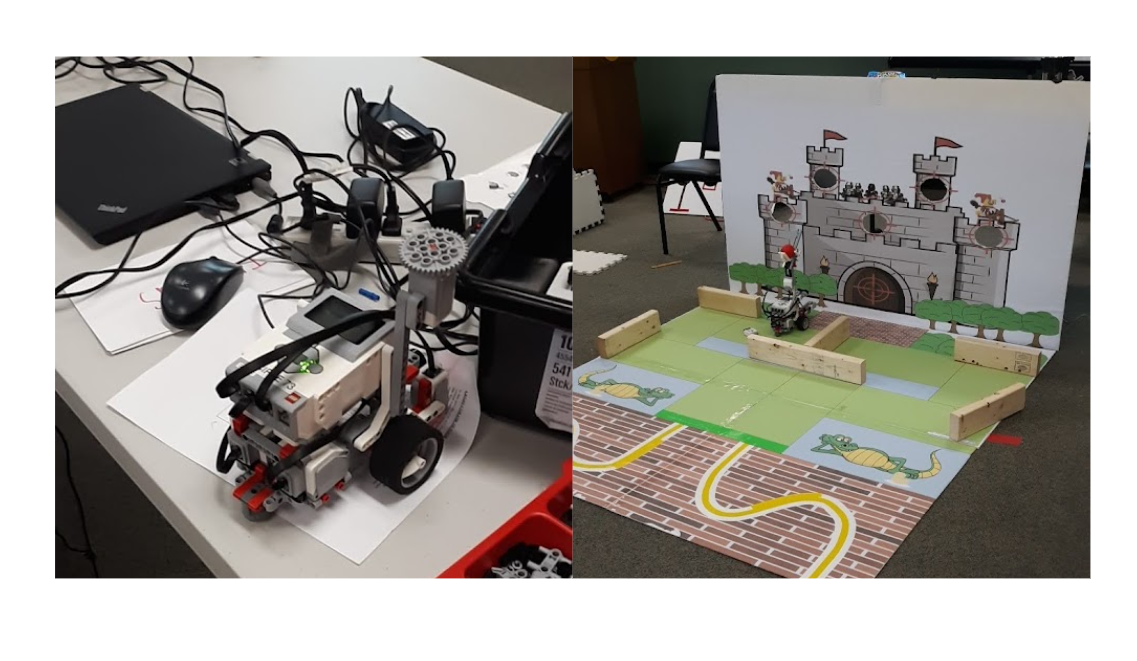

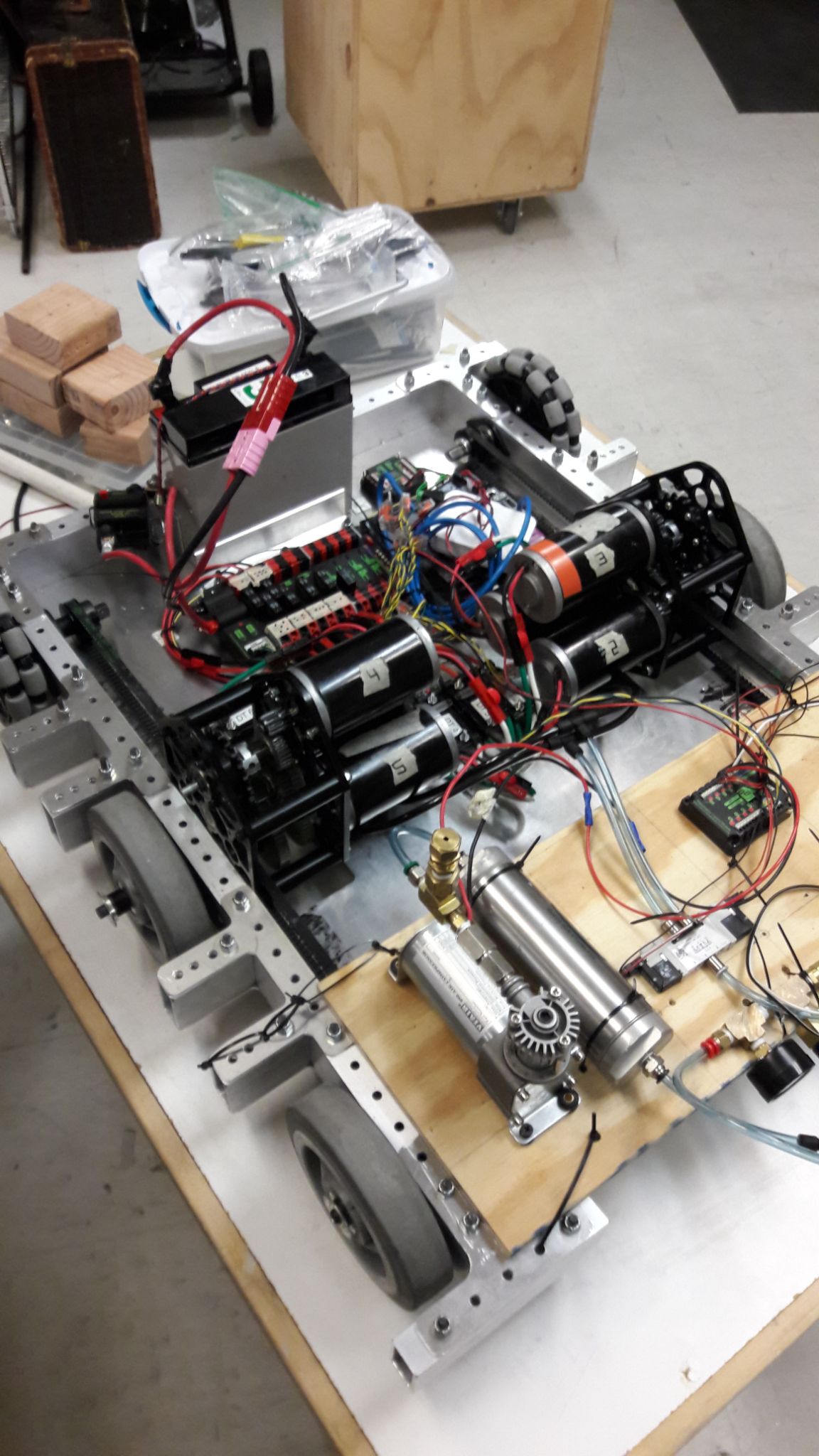

Skills applied: 3D

printing(ABS, Carbon Fiber, PLA, TPU), Hand Tools, Lift Mechanism, Linkage and Gear

Mechanism, Machine Shop Tools, Motors, Pneumatic, Project Management, Prototyping,

Soldering, SOLIDWORKS, Wiring.

Led Team 4454 of 20+ teammates in the FIRST

Robotics Competition.

Led 2+ subsystems of 4+ teammates each year and assisted other subsystems at any

opportunity.

Became proficient in the engineering design process and participated in the

research, design, prototype, CAD, and assembly of 3+ robots, and mentored new

teammates.

Skills applied: 3D

printing(ABS, Carbon Fiber, PLA, TPU), Hand Tools, Lift Mechanism, Linkage and Gear

Mechanism, Machine Shop Tools, Motors, Pneumatic, Project Management, Prototyping,

Soldering, SOLIDWORKS, Wiring.

Led Team 4454 of 20+ teammates in the FIRST

Robotics Competition.

Led 2+ subsystems of 4+ teammates each year and assisted other subsystems at any

opportunity.

Became proficient in the engineering design process and participated in the

research, design, prototype, CAD, and assembly of 3+ robots, and mentored new

teammates.

The picture portrays a 1:16 scale model of the

team's robot, meticulously crafted using its CAD design and partially fabricated on

the laser cutter to produce microscale components.

The picture portrays a 1:16 scale model of the

team's robot, meticulously crafted using its CAD design and partially fabricated on

the laser cutter to produce microscale components.

Skills applied: 3D

Printing, Arduino, Bluetooth, C++, Design Report, Fusion 360, LCD, Power System,

Project

Development, Schematics, Soldering, SOLIDWORKS, Wiring.

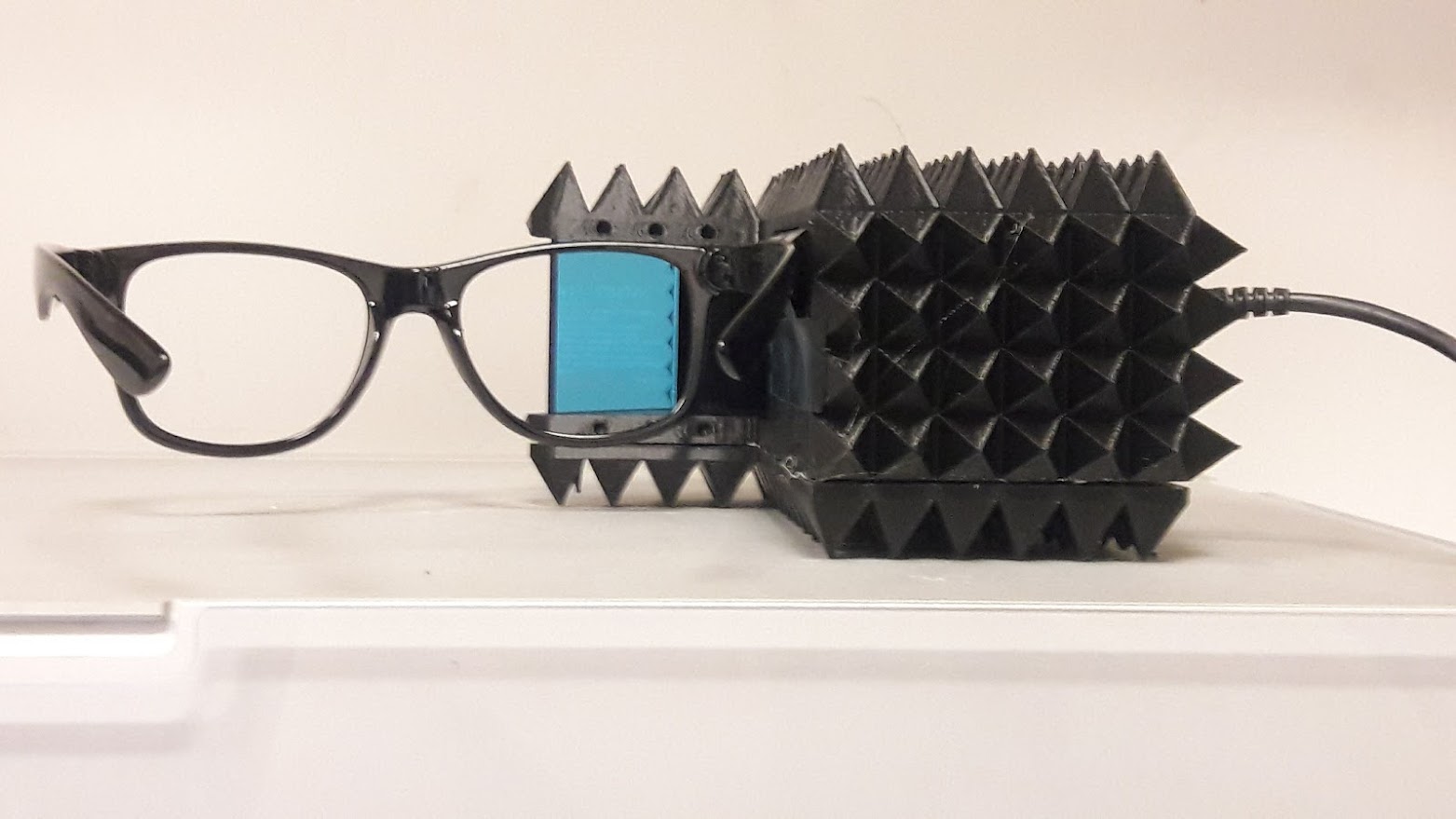

The image showcases a pair of futuristic glasses

incorporating an Arduino Nano, designed to project words onto a translucent acrylic

lens. This innovative technology enables users to read information from the screen

while

maintaining awareness of their real-life surroundings.

Skills applied: 3D

Printing, Arduino, Bluetooth, C++, Design Report, Fusion 360, LCD, Power System,

Project

Development, Schematics, Soldering, SOLIDWORKS, Wiring.

The image showcases a pair of futuristic glasses

incorporating an Arduino Nano, designed to project words onto a translucent acrylic

lens. This innovative technology enables users to read information from the screen

while

maintaining awareness of their real-life surroundings.

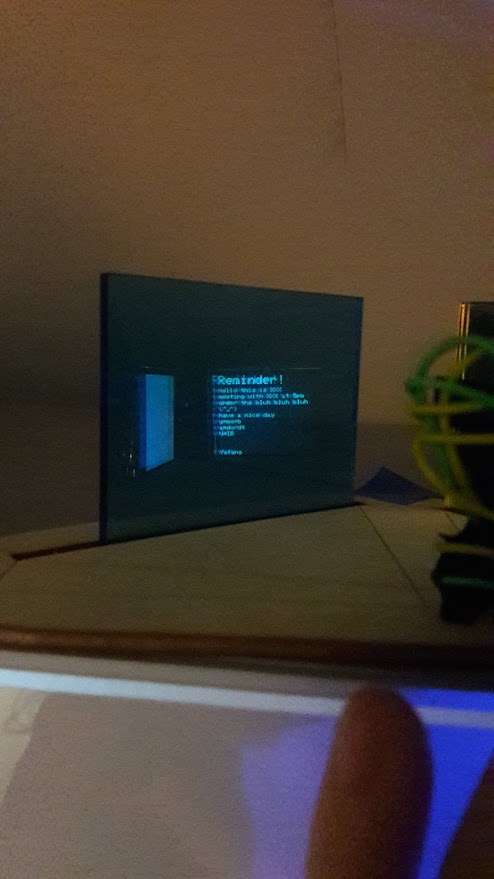

The image depicts testing procedures where a

translucent acrylic sheet is utilized as a monitor screen, showcasing its viability

for

this application.

The image depicts testing procedures where a

translucent acrylic sheet is utilized as a monitor screen, showcasing its viability

for

this application.

Skills applied:

LED, Power System, Prototyping, Sewing.

Skills applied:

LED, Power System, Prototyping, Sewing.

The image showcases the electronics and

power sources embedded under a light-up skirt, which are the mechanisms that

powering the illumination.

The image showcases the electronics and

power sources embedded under a light-up skirt, which are the mechanisms that

powering the illumination.

The image showcases the lightup skirt in

the twilight sky.

The image showcases the lightup skirt in

the twilight sky.

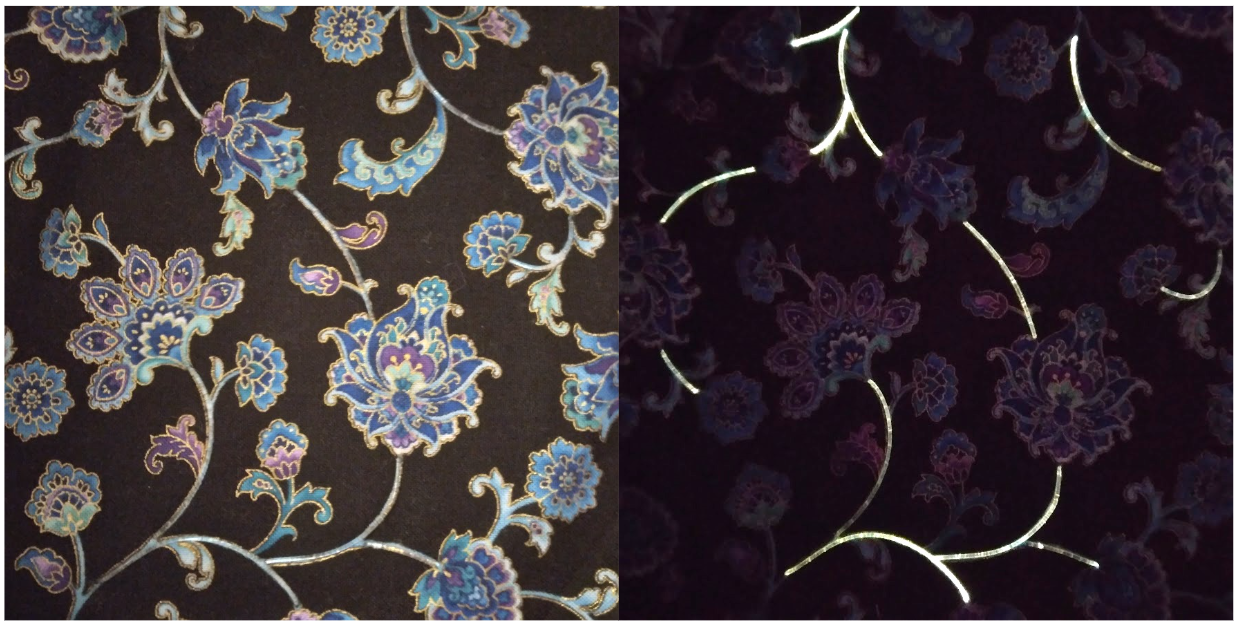

Skills applied:

Adobe Illustrator, Laser Cutter.

This series of projects delved into an

array of laser cutting techniques, encompassing intricate engraving, precise

cutting, and manipulation of material properties through pattern cutting. A

diverse range of materials, including gemstone, ultra-thin paper (0.10mm

thick), and fabric, were also incorporated.

Skills applied:

Adobe Illustrator, Laser Cutter.

This series of projects delved into an

array of laser cutting techniques, encompassing intricate engraving, precise

cutting, and manipulation of material properties through pattern cutting. A

diverse range of materials, including gemstone, ultra-thin paper (0.10mm

thick), and fabric, were also incorporated.

The images showcases meticulously laser cut and

engraved paper pieces of exceptionally small size, highlighting the precision

achievable with this technology.

The images showcases meticulously laser cut and

engraved paper pieces of exceptionally small size, highlighting the precision

achievable with this technology.

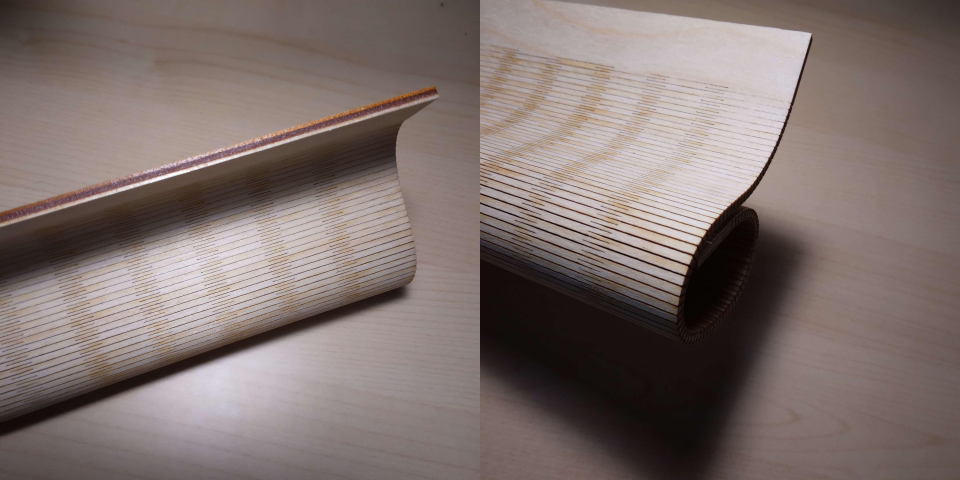

The image showcase wood being laser-cut into a

living hinge using a specialized pattern, transforming a piece of solid wood into a

flexible component. This demonstrates the versatility of laser cutters in altering

material properties.

The image showcase wood being laser-cut into a

living hinge using a specialized pattern, transforming a piece of solid wood into a

flexible component. This demonstrates the versatility of laser cutters in altering

material properties.

The image showcases a laser-cut wooden piece,

demonstrating both cutting and engraving techniques achieved through laser

technology.

The image showcases a laser-cut wooden piece,

demonstrating both cutting and engraving techniques achieved through laser

technology.

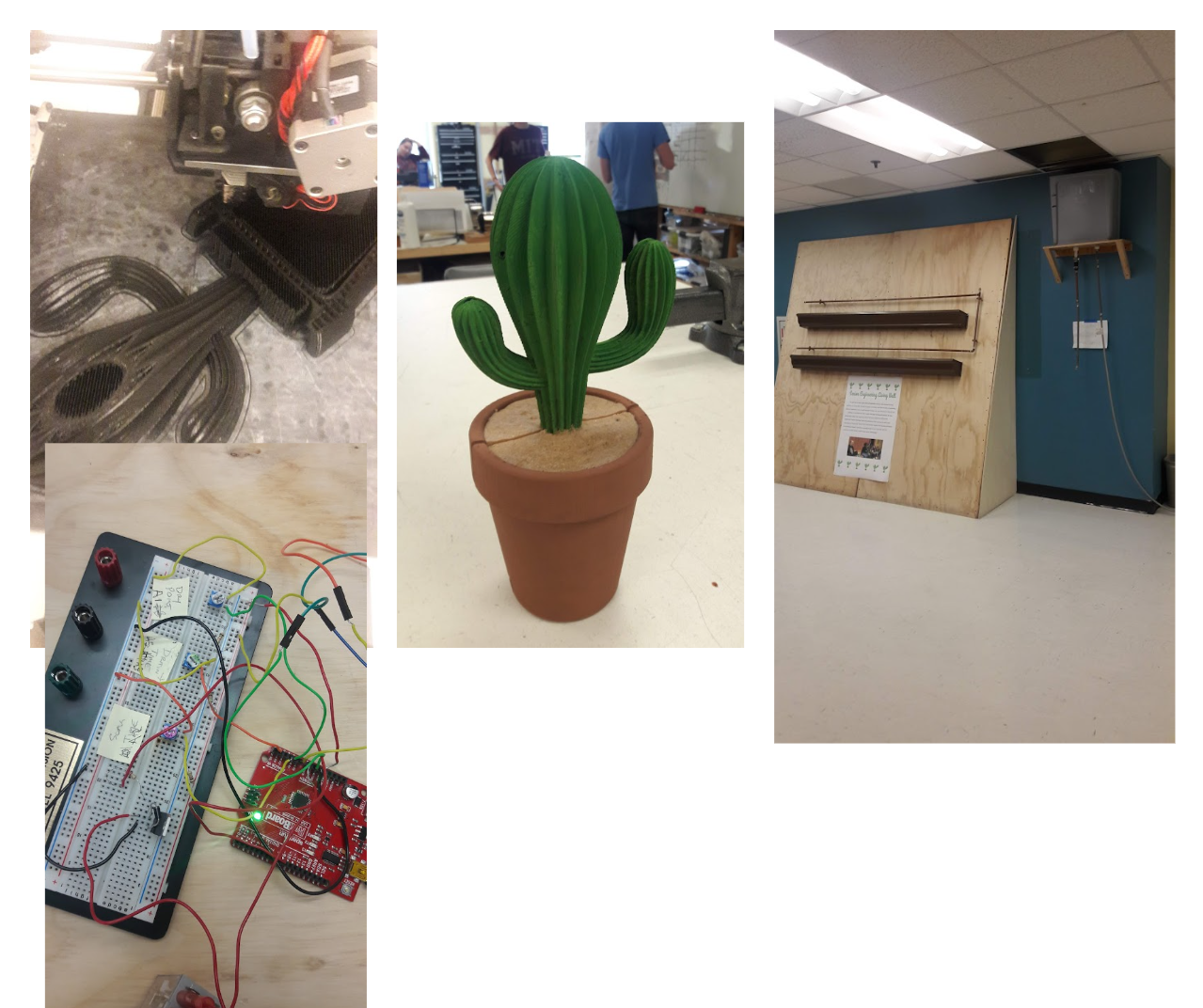

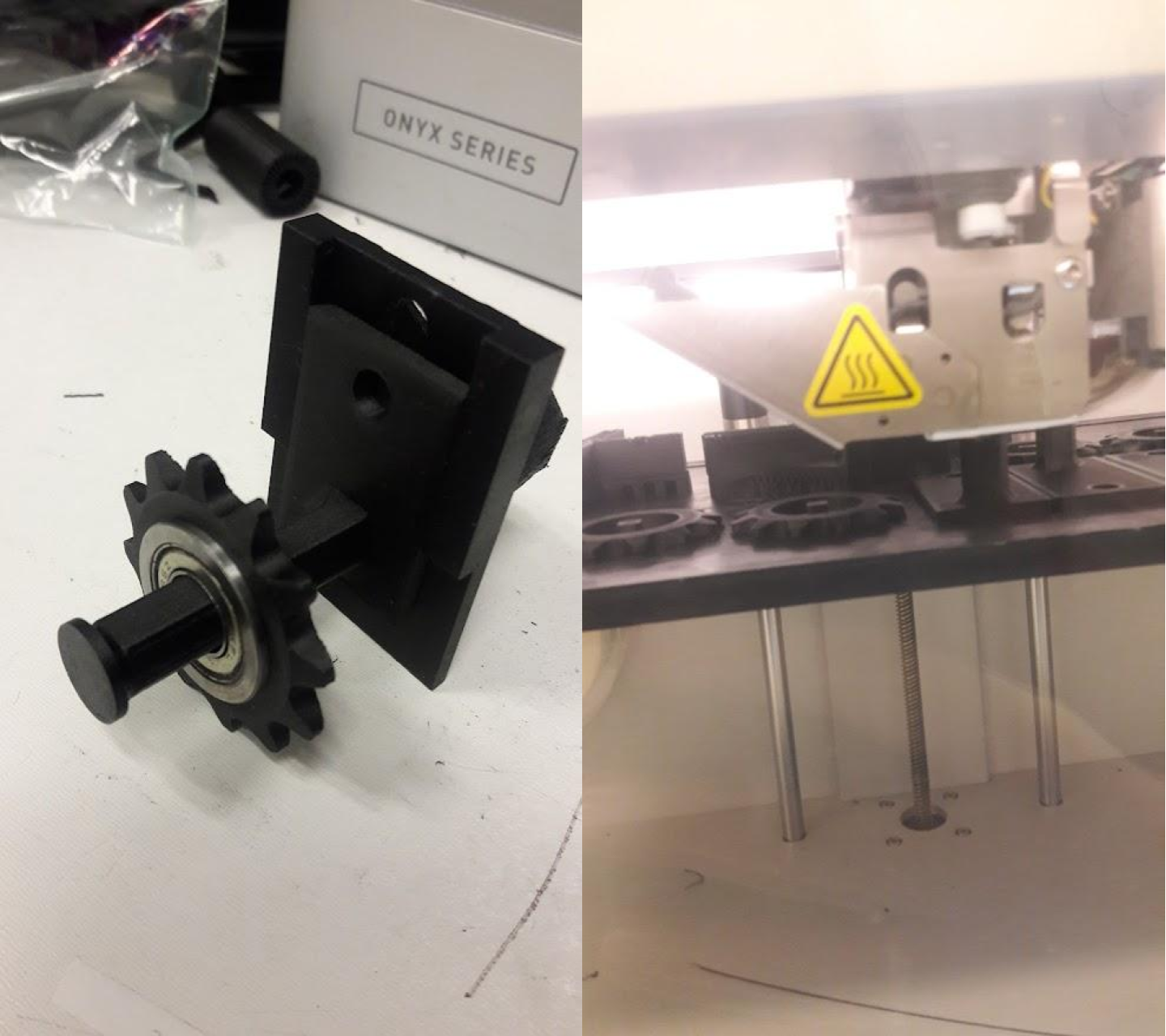

3D printing(ABS, Carbon

Fiber, PLA, TPU), Auotodesk Fusion 360, CAD, Siemens NX, SOLIDWORKS, Tolerance

Calculation, Troubleshooting.

Utilizing SOLIDWORKS CAD, the 3D printing and

performance evaluations of a carbon fiber reinforced gear mechanism were conducted,

showcasing proficiency in CAD design and thorough understanding in material

selection for mechanical applications.

3D printing(ABS, Carbon

Fiber, PLA, TPU), Auotodesk Fusion 360, CAD, Siemens NX, SOLIDWORKS, Tolerance

Calculation, Troubleshooting.

Utilizing SOLIDWORKS CAD, the 3D printing and

performance evaluations of a carbon fiber reinforced gear mechanism were conducted,

showcasing proficiency in CAD design and thorough understanding in material

selection for mechanical applications.

The images depict a cactus shaped electronics

holder designed and rendered through Fusion 360 and then 3D printed, highlighting

proficiency in diverse CAD programs and additive manufacturing, while also

presenting a fun challenge for mastering novel techniques.

The images depict a cactus shaped electronics

holder designed and rendered through Fusion 360 and then 3D printed, highlighting

proficiency in diverse CAD programs and additive manufacturing, while also

presenting a fun challenge for mastering novel techniques.

The images depict the designing and 3D printing of

a grappling hook for testing purposes without utilizing any printing supports,

demonstrating proficiency in CAD design and 3D printing techniques for complex

objects.

The images depict the designing and 3D printing of

a grappling hook for testing purposes without utilizing any printing supports,

demonstrating proficiency in CAD design and 3D printing techniques for complex

objects.

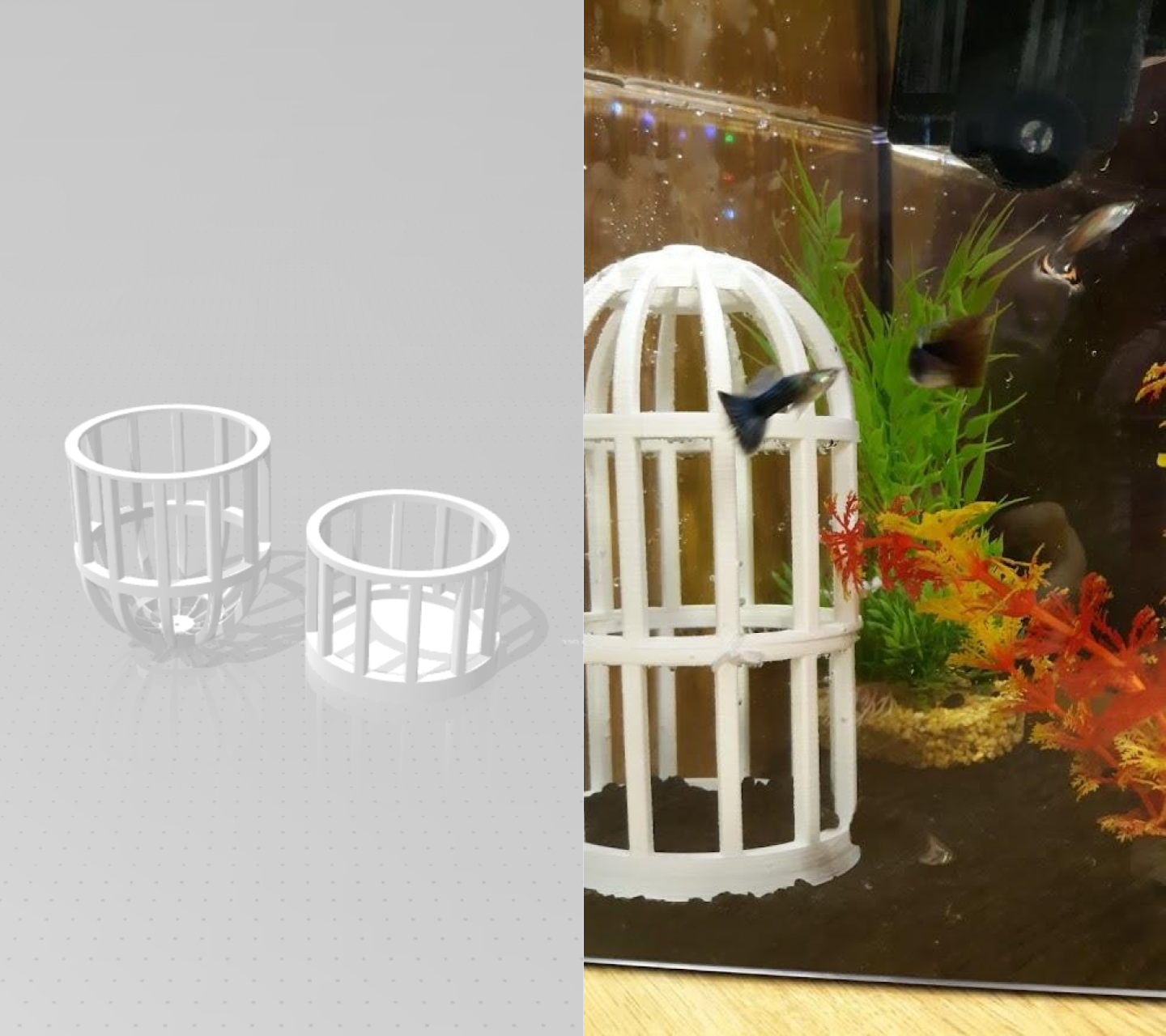

The images depict the designing and 3D printing of

a bird cage with a configuration optimized for support-free printing, demonstrating

mastery in both design and efficient 3D printing techniques

The images depict the designing and 3D printing of

a bird cage with a configuration optimized for support-free printing, demonstrating

mastery in both design and efficient 3D printing techniques